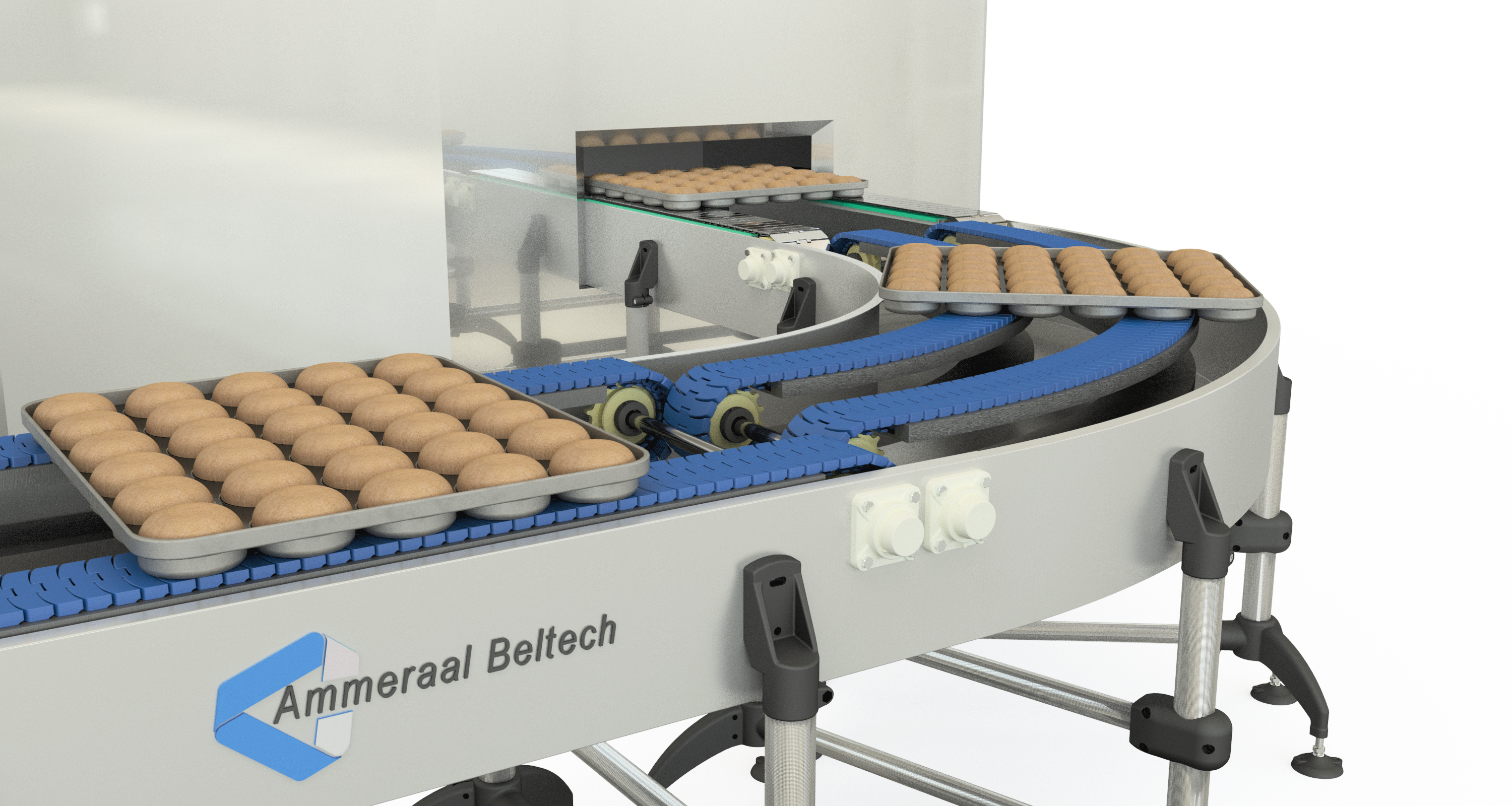

New side flexing conveyor chain – uni 253 and 255

To meet the challenges in cooling deformation and chain weight, we’ve made improvements to the products we already have in our product portfolio, and developed a new, thicker, but lighter conveyor chain series. The uni 253 and uni 255 are modular plastic chains that have been designed with a specific emphasis on plate thickness to overcome the challenges faced by the bakery, beverage, and glass container manufacturing industries.

These side flexing chain series ensure exceptional product stability during lateral movements and smooth transitions between chains and modular belts, providing maximum product safety throughout the entire conveying process.

Product details

The belt’s pitch is 25.4 mm (1” in). The thickness equals 8.7 mm (0.34 in) for uni 253 and 12.7 mm (0.5 in) for uni 255.

Bevel, TAB, and magnetic hinges are available for uni 253. TAB and magnetic hinges are available for uni 255.

The top surface for uni 253 can be flush grid (FG) or flat top (FT). The top surface for uni 255 is flat top (FT).

The belt fits industry standard 880 / 879 / 881 conveyor track.

There are supporting products available. Sprockets are a must, and there are also components such as curves, tracks, wearstrips, etc.

Features

Optimal performance and reliability – the chains can be used in a wide range of applications, low and high speed, as well as mass and single conveyors on both side-flexing and straight-running lines.

Ultimate wear resistance – heavy-duty thickness withstands high workload capacity.

Improved stability of product transport and lateral transfers and less pulsation risk and polygonal effect. It’s all thanks to top-flight flatness and reduced gaps between links. The series optimizes container handling and minimizes downtime caused by product spillage.

Reduced total cost of ownership and energy efficiency. The belt is lightweight, but without compromising strength.

Download uni 253-255 publication.